Helpful Articles

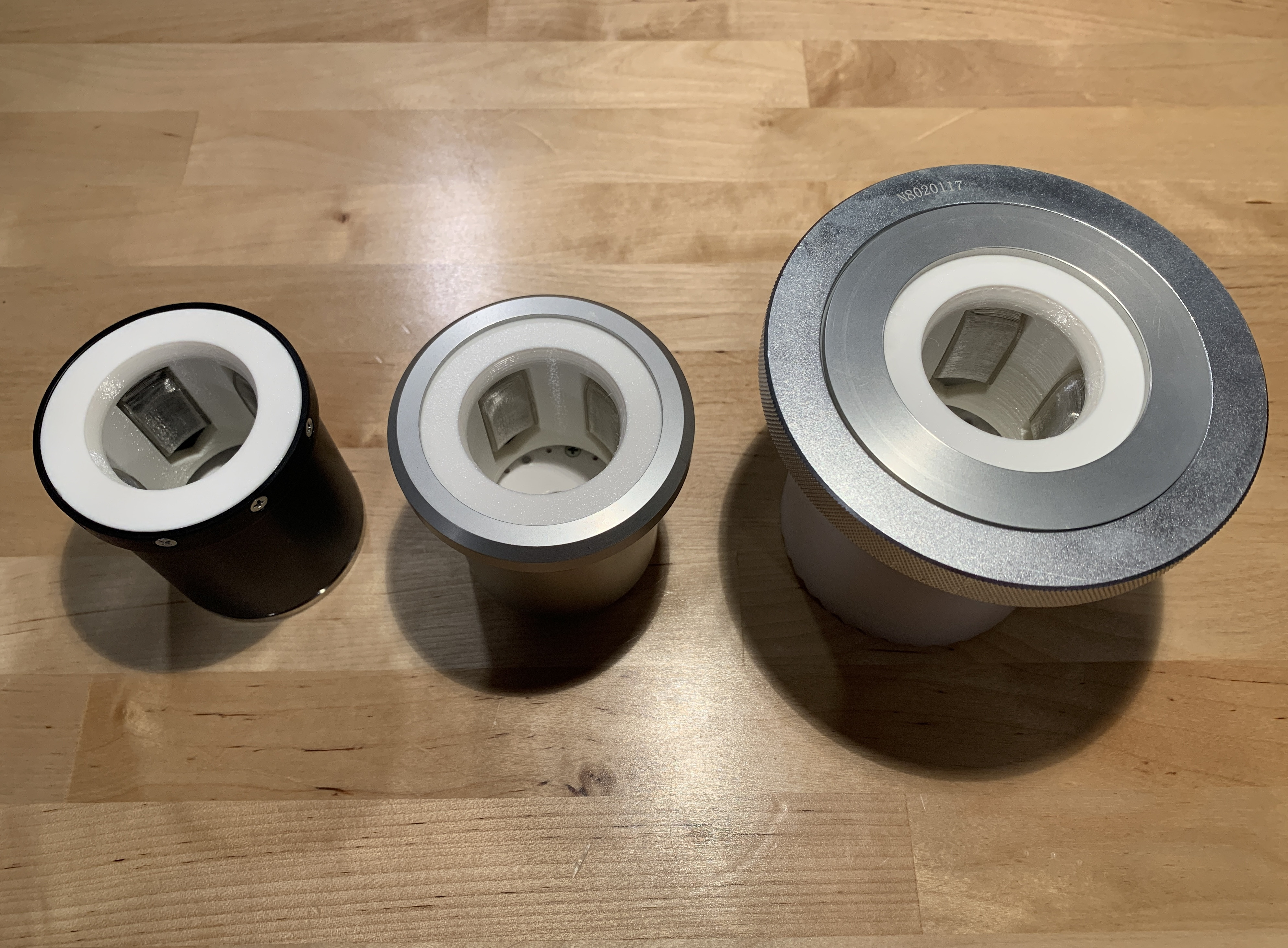

One of the most notable features of our 3D printed tube holder inserts (Flex Pucks) and modular spacers is that they are universal across tube sealers from multiple manufacturers. Cut down on costs and improve the efficiency of your business by utilizing the same style of tube holder inserts and spacers for your Neweco, Kalix, and other tube filling and sealing machines such as the TFS-80. See how easy it is to swap tooling between tube holder styles in the video below.

Universal 3D printed tooling as shown above offers many benefits to your tube filling and sealing operation. If you decide to upgrade to another machine model, you can utilize the tooling you already own and only purchase what is necessary to fill additional spaces on a higher-capacity machine.

The first style of tube holder shown in the video is for a TFS-80 automatic tube filling and sealing machine. Our two-piece aluminum insert adapters allow you to quickly and easily swap your Neweco or Kalix tooling to a TFS-80 machine. Simply place your Flex Puck and spacers into the aluminum adapter and screw-down the top ring. Read more on our full sets of TFS-80 tooling here.

Next is a Kalix style tube holder. No adapters are required here, just insert your Flex Puck and spacers and secure the assembly with the screw-down ring.

Finally, we see a Neweco style tube holder. These shells are CNC machined from high-quality Delrin plastic and stainless steel. A different style of angled bottom spacer is used here, and fastened to the universal flat spacer. Then, the Flex Puck is inserted and secured with nine self-tapping screws. Neweco tube holders will work across all their tube sealing machine models. Read more on our full sets of tooling for automatic tube filling machines here.

Feel free to reach out and contact us with any questions.