March 6, 2023

Traditionally, most size parts/change parts on any given tube filling and sealing machine would be CNC cut from various metals and hard plastics. However, with modern additive manufacturing technology, 3D printed end-use tooling offers impressive advantages.

Traditionally, most size parts/change parts on any given tube filling and sealing machine would be CNC cut from various metals and hard plastics. However, with modern additive manufacturing technology, 3D printed end-use tooling offers impressive advantages.

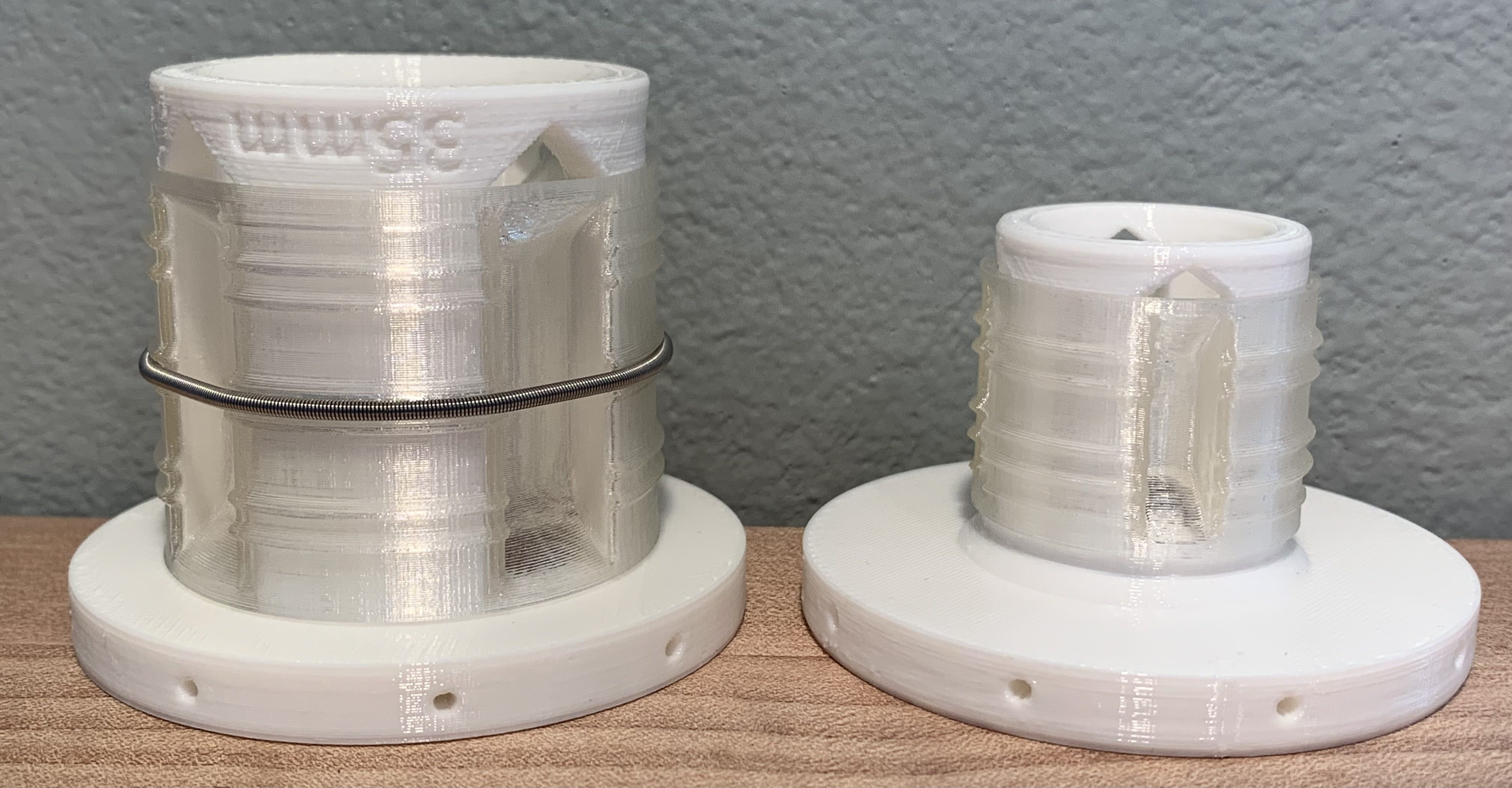

Our tube holder inserts, also called Flex Pucks, are 3D printed from thermoplastic polyurethane (TPU). TPU has several qualities that make it ideal for use as tooling in tube sealing machines, such as high abrasion resistance, high shear strength and elasticity, and excellent resistance to oils, greases, and chemicals. The exceptional mechanical properties allow our Flex Pucks to be run for hundreds of thousands of machine cycles with virtually zero signs of wear. As you can see in the video below, even after being crushed in a vise, the Flex Puck immediately returns to its original shape without any damage.

The two-piece design of our Flex Pucks allows us to combine different TPUs, which is necessary to achieve the perfect sweet spot between rigid and flexible. The white frame of the Flex Puck is a harder TPU, which provides structure for the transparent band and prevents the tube from leaning too far to one side or the other. The transparent band is an extremely flexible and soft TPU, great for gripping tubes of various sizes and surface finishes. With the ability to add up to three tensioning springs to the Flex Puck at different heights, the operator can easily adjust the fitment of the tube holder inserts.

Flex Pucks for Oval Tubes

Oval tubes can be tricky to load and hold properly, especially on fully automatic tube sealing machines. On hand load machines, oval-bore tube holder inserts are an option because the operator can simply orient the tube correctly. However, automatic machines will load oval tubes at whichever orientation they end up at on the vacuum loading block, so it is important to use round-bore inserts.

“How will a round insert hold an oval tube?”

Due to the high elasticity of TPU, we can produce a round insert that conforms to the shape of the oval tube when it is loaded. In the video below, you can see even the stiffer white frame will flex to properly hold the tube and then return to its original shape after the tube is ejected.

Feel free to reach out and contact us with any questions.

USA Sales & Service

USA Sales & Service