May 20, 2024

The Challenge: Need to put your product into a squeeze tube, where do you start? So many types of tubes... extruded mono/coex, laminate, injection-molded, confused yet? It's very important to choose a tube that will match your sealing machine capabilities. The Whole Package has 25 years in tubes, let us help you pick the best tube for your application. There are most commonly 3 Levels of tube sealing technology used in the industry today, starting with the best:

Level 3 (hot-air sealing, short-run production jobs):

Level 3 (hot-air sealing, short-run production jobs):

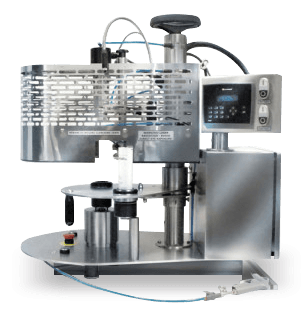

Table-top Hot Air Tube Sealing Machine. Pricing starts at $20,000. This machine uses the same professional level hot-air sealing technology found in high speed fully automatic machines. Hot air seals are produced with speeds up to 15 tubes per minute. This machine is also available in metal fold versions for crimping aluminum tubes.

Click for our tube sealing machine options...

Pros: Professional seals on ALL plastic and laminate tubes. Many new resins used in sustainable tubes will only seal with hot air, such as fully recyclable in-mold label tubes (IML tubes). Laminate tubes with foil layers or Polyfoil tubes work best on hot-air machinery.

Pros: Lot coding is available on both sides of the tube seal. Machines are lightweight, easily movable and use standard 110v electric. Ideal for quick changeover production runs.

Cons: For a tabletop tube sealer, this machine excels in all areas.

Level 3 (hot air sealing, large production runs):

Level 3 (hot air sealing, large production runs):

Fully-Automatic Hot-Air Tube Filling & Sealing Machine. Pricing starts at $90,000. Tube is auto-loaded into machine, filled, hot-air melts the open-end then jaws squeeze to seal. Speeds up to 40 tubes per minute, changing tube sizes can take 2+ hours requiring a mechanic.

Click for our new machinery selection...

Pros: Professional tube seals with vertical seal pattern, date/lot coding and tube seal trimming.

Pros: High speed filling & sealing, great for doing production runs of 10,000+ tubes per day.

Cons: Requires custom size parts tooling for each unique tube size. Requires trained operators & mechanics.

Level 2 (ultrasonic sealing, R&D samples):

Level 2 (ultrasonic sealing, R&D samples):

Semi-Automatic Ultrasonic Tube Sealing Machine. The tube is squeezed between a set of heat-generating high frequency ultrasonic sealing jaws. Real use speeds of 4-7 tubes per minute.

Pros: Works with a variety of plastic tubes, but some tubes are problematic, such as PP tubes.

Cons: Foil layer laminate tubes are difficult to seal and usually result in poor seal quality.

Cons: Will damage labels or other artwork in the seal area.

Cons: Requires constant adjustment of sealing parameters to maintain consistency which slows down through-put.

Level 1 (thermal impulse sealing, lab samples):

Level 1 (thermal impulse sealing, lab samples):

Manual Thermal Impulse Tube Sealing Machine. The tube is squeezed between a hot element which works similar to a hot iron to melt the tube. Real use speeds of 2-5 tubes per minute, must manually level the tube shelf for straight seals.

Click for our tube sealing machine options...

Pros: Lowest cost option to seal tubes, easy to use, lightweight, portable, no tooling.

Cons: Unattractive seal quality, no date/lot coding, no trimming, works with limited tube materials.

USA Sales & Service

USA Sales & Service